Working for Decmil Australia, TopTroniX was engaged to upgrade the communications infrastructure of the existing Fuel Farm 3 at RAAF Base Darwin.

The existing inter-RTU communications was achieved using RS232 / RS422 serial <-> fibre optic modems, using dedicated fibre optic cabling between each RTU. However, this infrastructure didn’t lend itself well to fault finding, easy expansion, or support for future products.

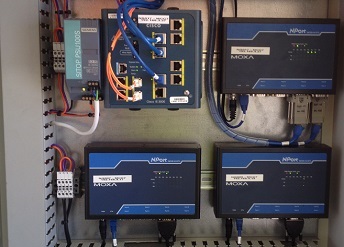

So, TopTroniX designed, programmed, tested and commissioned a Cisco IE-3000 switch infrastructure throughout the farm. We re-tasked the existing fibre optic cabling, so no new cables were required to be hauled in… and we made use of Moxa serial <-> ethernet gateways, so no modifications to the existing inter-RTU coding was required. Using this approach allowed us to stage the cut-over to the new communications equipment, which meant minimal downtime to the RAAF. So much so, that to cut-over over 24 individual devices required a loss of total functionality for only a couple of hours.

Once the new infrastructure was in, additional comms links to the RTU’s meant the SCADA system could be brought back up to its original speed, which had degraded over years of expansions.

The end result? A stable, reliable communications backbone using industry leading network equipment, with better diagnostics… and a group of happy operators, as the farm was responding better than it had in years.